Various fabrication techniques can be employed to fabricate Eva Bond Aluminium Composite Panels. It is recommended to carry out fabrication in a workshop to minimise defects, exercise overall quality control and to attain higher levels of accuracy.

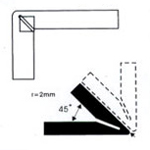

The material can be fabricated by employing the right tools. The blade configuration and the cutting conditions should be carefully selected to ensure that frictional forces are minimized and the heat produced during the process is also kept to the minimum.

Panels ought to be erected in accordance with an approved set of shop drawings. In addition structural strength of anchorage and assorted hardware used for fastening should be as per standards and preferably of aluminium as per engineering recommendations.

Wherever aluminium comes in contact with dissimilar metals, it should be properly insulated else use of caulking tape is advised to avoid electrolytic corrosion.

The bend portions between panel joints shall not be caulked before the protective film is removed. Ensure weep holes and drainage channels are unobstructed and free of debris, dirt and sealant.

It is recommended to install the panel vertically.

Routine cleaning of the ACP surface is recommended. It may be washed with water and mild detergent, followed by clean water rinse. The frequency with which cleaning is to be carried out and the choice of a suitable cleaning agent depends largely on the location of the building and levels of contamination.

Do not clean when surface temperatures are above 40 degree centigrade to avoid formation of stains.

The cleaning operation must be carried out from top to bottom followed by proper rinsing with clean water to ensure the removal of the cleansing agent residues. A final wipe down by means of a sponge, leather or a wiper is necessary to avoid water stains.